Speed and efficiency

With the Luminous hydraulic press, you can press all types of fillings of various weights and thicknesses with a single press of a button. Let the power of the press, its stable temperature, and automatic timer-controlled pressure handle the rest efficiently

A long-term relationship

It reflects our commitment to providing a reliable product that enhances your production efficiency, combining advanced technology and high quality to achieve outstanding results with continuous support and maintenance

Durable product

It is the perfect solution for industrial operations requiring reliable performance and high durability. With advanced German technology and professional maintenance, the press ensures efficient and effective production, making it a valuable long-term investment.

About Luminous Press

We offer you the best hydraulic filling press with the highest standards.

Every factory and workshop that produces clothes needs to use the best machines and equipment, the quality of which will be reflected in the quality of the final product on which the name of a successful brand is built, which focuses on the trust of its customers.

- High-quality parts for a lasting investment.

- 2 HP hydraulic cylinders

- Temperature up to 200°C

- Pressing force up to 10 tons

- Full warranty on all parts

- Free maintenance for 2 years

High quality parts

Eco Mode

Silent pressing system

How do we make quality?

Steps to make a piston

1. Well-designed engineering

The process begins with 3D development using advanced engineering modeling software based on German technology.

2. Materials and production

Durable materials are chosen for high pressure and long life. Advanced tech ensures precise manufacturing

3. Assembly and calibration

Parts are precisely assembled to German standards, then calibrated to meet performance specs.

4. Testing and quality assurance

The press undergoes strict tests for pressure, accuracy, and durability to meet German and Saudi standards.

After serving over 900 clothing establishments in the textiles sector and understanding their needs, we are dedicated to providing practical and efficient solutions to support our clients

Abdullah alamoudi

CEO

About Luminous

Luminous is a division of Raqi Textile Company, focused on hydraulic presses.

Luminous serves a large sector of the clothing industry, especially men’s clothing such as dresses and shirts, as it offers one of the most important pieces with all its accessories, which is the hydraulic presses that clothing factories and garment factories rely on to press fillings of various types and weights.

- The press improves the quality of all filling types

- The press retains required pressure strength for decades

- The press relies on an eco mode system to save energy

- Simple control with a user-friendly settings screen

- Available parts, warranties, and expert maintenance

- Made from durable materials to ensure a long lifespan

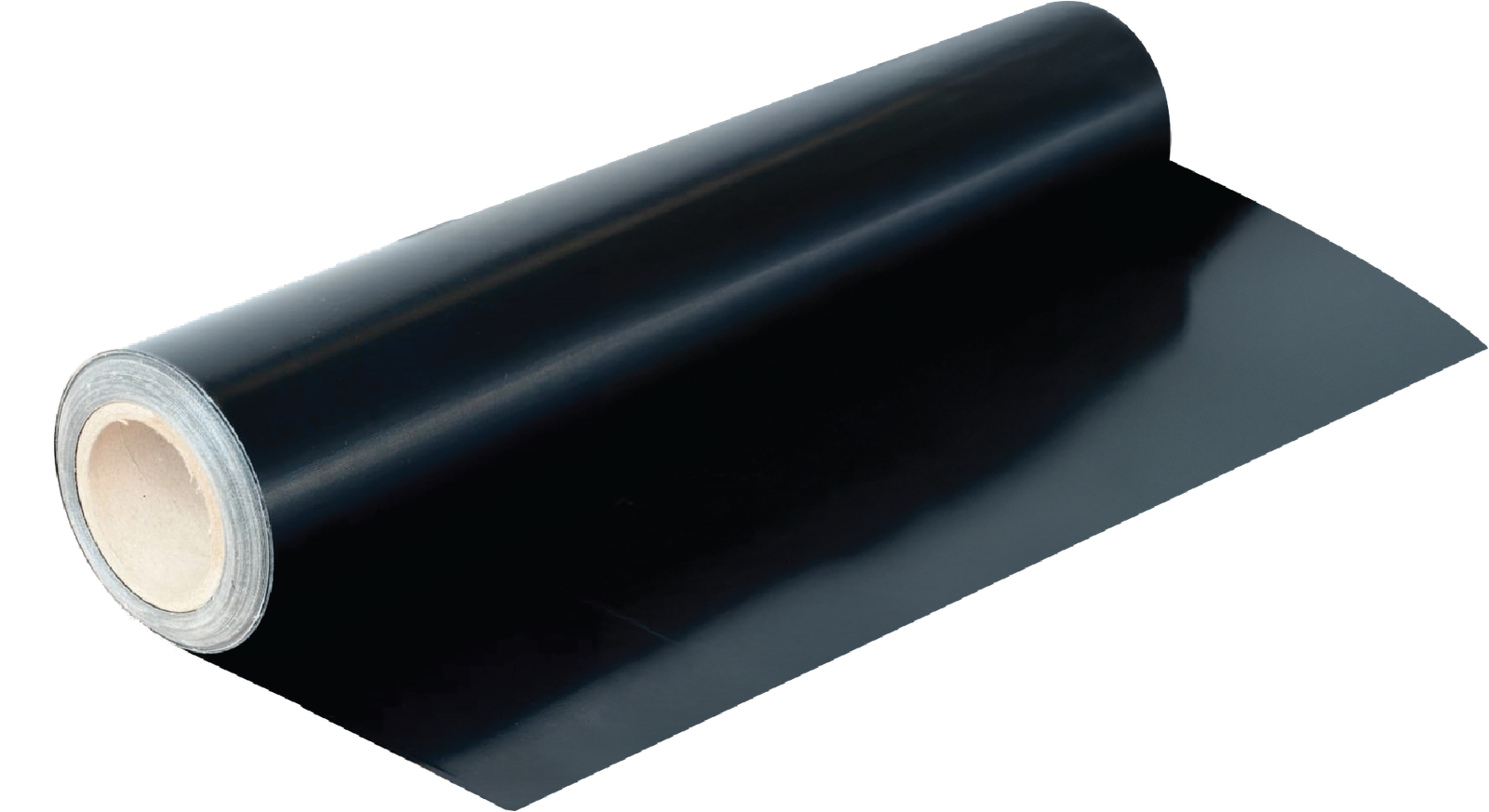

- Provides perfect compatibility with the press

- Enables quick, secure installation

- Notable for withstanding environmental factors

- Made from durable materials that withstand heavy use

- We use advanced tech for quick fault detection

- Our team consists of skilled technicians

- Quick maintenance services

- We guarantee damaged parts replacement

- Quick emergency maintenance services

Operational products

Complementary products

High-temperature, pressure-resistant, breathable surface of quality materials

It resists oxidation for long-term performance and withstands high pressure and heat

Features air release pores, resists high temperatures, and is durable

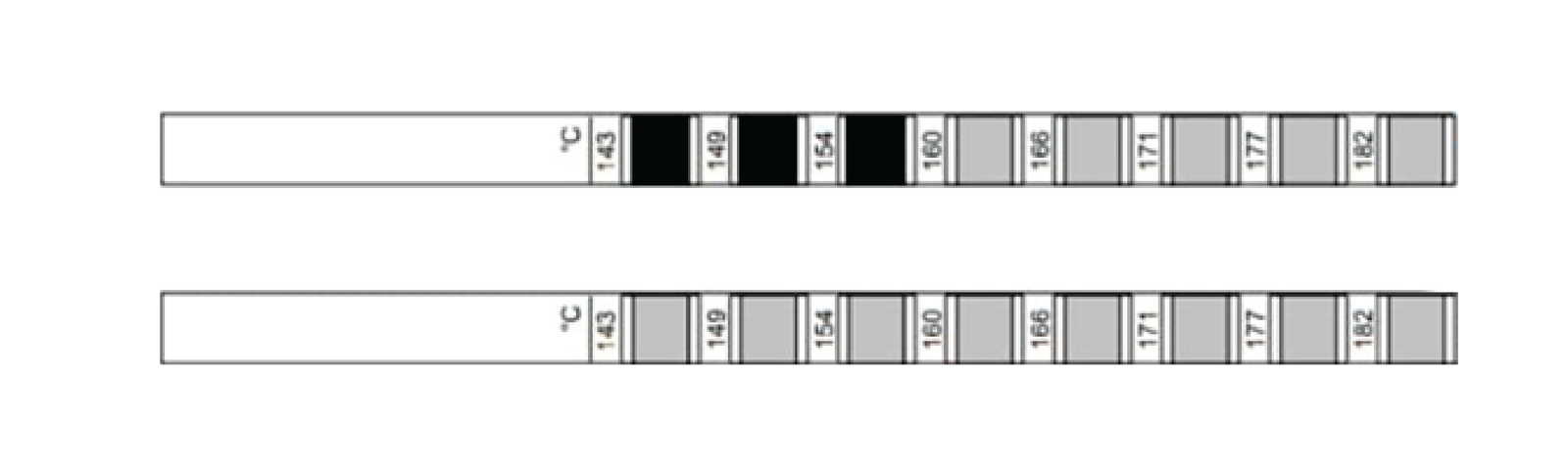

Reliable temperature measurement with quick response and accuracy

1. What are the key features of the Luminous hydraulic filling press?

The Luminous hydraulic filling press features advanced German technology, making it ideal for industrial operations that require high precision and efficiency. With its reliance on German-made spare parts, the press offers significant reliability and long-lasting durability without the need for frequent maintenance. Additionally, our professional maintenance services ensure the press continues to operate efficiently, with easy access to original spare parts, reducing unplanned downtime.

2. What type of hydraulic oil is suitable for use with the press?

The Luminous hydraulic filling press relies on hydraulic oils of type ISO VG 46 or ISO VG 68. These oil types provide an ideal balance between good lubrication and high oxidation resistance, ensuring stable press performance even in harsh conditions. They are also designed to withstand high pressure and offer excellent protection for internal components, such as cylinders and pumps, extending the press's lifespan and reducing maintenance costs.

3. What warranties come with the press?

The Luminous hydraulic filling press comes with a comprehensive warranty covering the main components for up to one year or more, depending on the agreement. The warranty includes coverage for mechanical or hydraulic failures that may arise due to manufacturing defects or materials. Additionally, we provide exceptional technical support to ensure quick resolution of any issues customers may encounter. In the event of a malfunction, a specialized team is dispatched to provide necessary maintenance and ensure the press continues to operate without prolonged downtime.

4. What is the expected lifespan of the press?

The lifespan of the press depends on usage and maintenance, but it is designed for long-term operation due to its high quality and regular maintenance.

5. How are faults handled and spare parts requested?

In the event of a malfunction in the Luminous hydraulic filling press, we offer fast and efficient maintenance services. You can contact the technical support team, who will diagnose the issue remotely or through an on-site visit. Original spare parts are readily and consistently available, ensuring quick replacement of damaged components and minimizing downtime.

6. What warranties come with the press?

The Luminous hydraulic filling press comes with a comprehensive warranty covering the main components for up to one year or more, depending on the agreement. The warranty includes coverage for mechanical or hydraulic failures that may occur due to manufacturing defects or materials. Additionally, we provide exceptional technical support to ensure a quick response to any issues customers may face. In the event of a malfunction, a specialized team is dispatched to perform necessary maintenance and ensure the press continues to operate without prolonged downtime.

Your questions

Frequently asked questions

Do you have any other questions?

Do not hesitate to contact us and ask your inquiry and our team will answer you

Methodology

Our working method

01

We assess your needs to find the best product and ensure electrical suitability

02

We deliver the Luminous hydraulic press to your factory and connect it electrically with high efficiency

03

We provide thorough training on all press features for professional operation.

04

We conduct regular inspections under maintenance contracts for long-term operation

Hydraulic presses

Sizes and specifications

Some other press issues

- Designed for shirt pressing only, not for garments

- Single hydraulic press

- Pressure force < 5 tons

- High electricity consumption

- Lack of annual maintenance contracts

- Weak after-sales service

Best sellers

Luminous large press

- 40x80

- Pressure force of 200 bar

- 2-horsepower hydraulic motor with cylinders

- Pressure force of up to 10 tons

- Features Eco Mode system

- Silent press for quiet and efficient operation

- 30x70

- Pressure force of 200 bar

- 2-horsepower hydraulic motor with cylinders.

- Pressure force of up to 10 tons

- Features Eco Mode system

- Silent press for quiet and efficient operation

- 27x65

- Pressure force of 200 bar

- 2-horsepower hydraulic motor with cylinders.

- Pressure force of up to 10 tons

- Features Eco Mode system

- Silent press for quiet and efficient operation

Reviews

Customer reviews of our services

Product Manager

Lectus vestibulum mattis ullamcorper velit sed ullamcorper morbi tincidunt. Urna duis convallis convallis tellus id. Mollis aliquam ut porttitor leo. Bibendum ut tristique et egestas quis ipsum suspendisse. Commodo ullamcorper a lacus vestibulum sed. Ipsum dolor sit amet consectetur. Blandit volutpat maecenas volutpat blandit aliquam etiam.Nisl condimentum id venenatis a condimentum vitae sapien pellentesque.

CEO

Lectus vestibulum mattis ullamcorper velit sed ullamcorper morbi tincidunt. Urna duis convallis convallis tellus id. Mollis aliquam ut porttitor leo. Bibendum ut tristique et egestas quis ipsum suspendisse. Commodo ullamcorper a lacus vestibulum sed. Ipsum dolor sit amet consectetur. Blandit volutpat maecenas volutpat blandit aliquam etiam.Nisl condimentum id venenatis a condimentum vitae sapien pellentesque.

Process Manager

Lectus vestibulum mattis ullamcorper velit sed ullamcorper morbi tincidunt. Urna duis convallis convallis tellus id. Mollis aliquam ut porttitor leo. Bibendum ut tristique et egestas quis ipsum suspendisse. Commodo ullamcorper a lacus vestibulum sed. Ipsum dolor sit amet consectetur. Blandit volutpat maecenas volutpat blandit aliquam etiam.Nisl condimentum id venenatis a condimentum vitae sapien pellentesque.

Contact us